Technical features The air volume and pressure range are large. The air volume and pressure range are large.

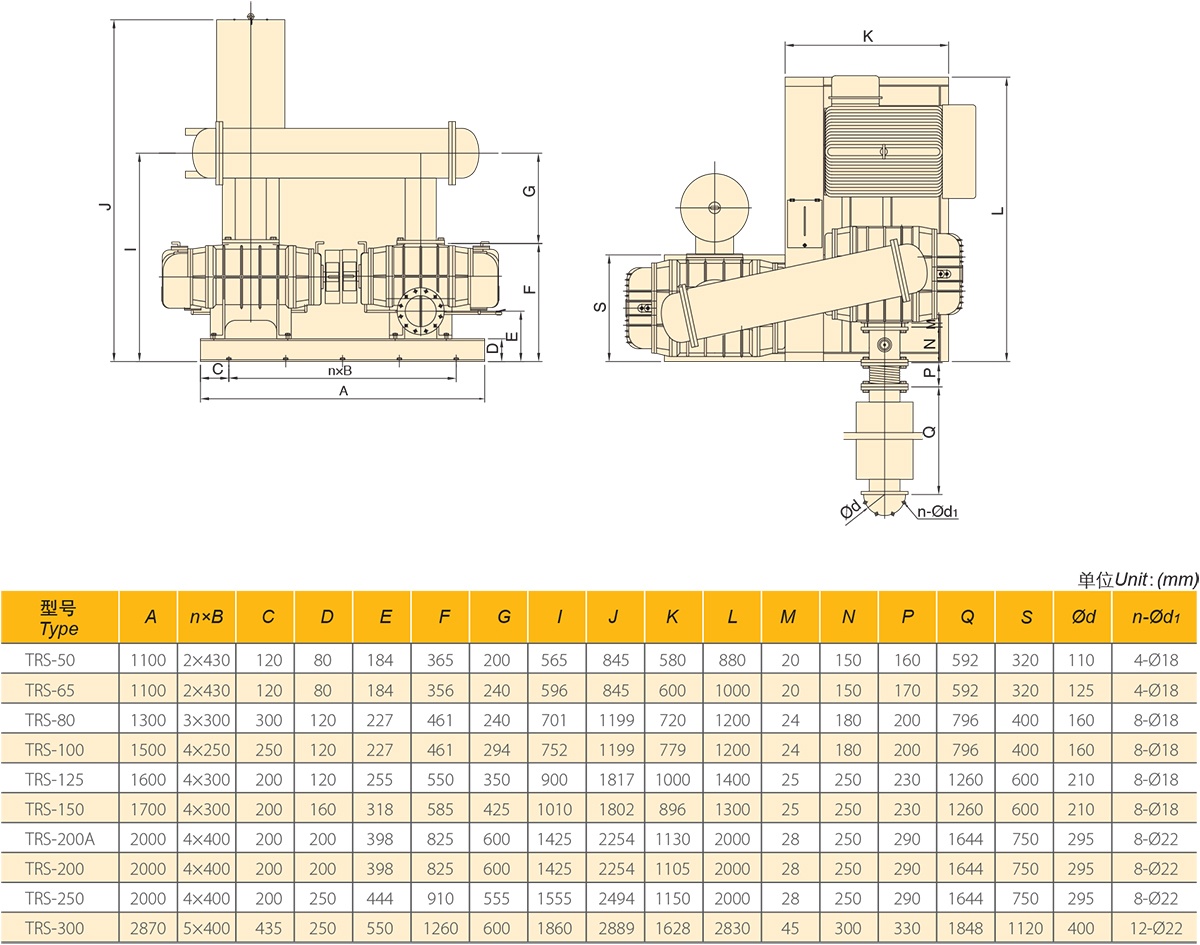

Caliber: 50mm~300mm (2”~12”)

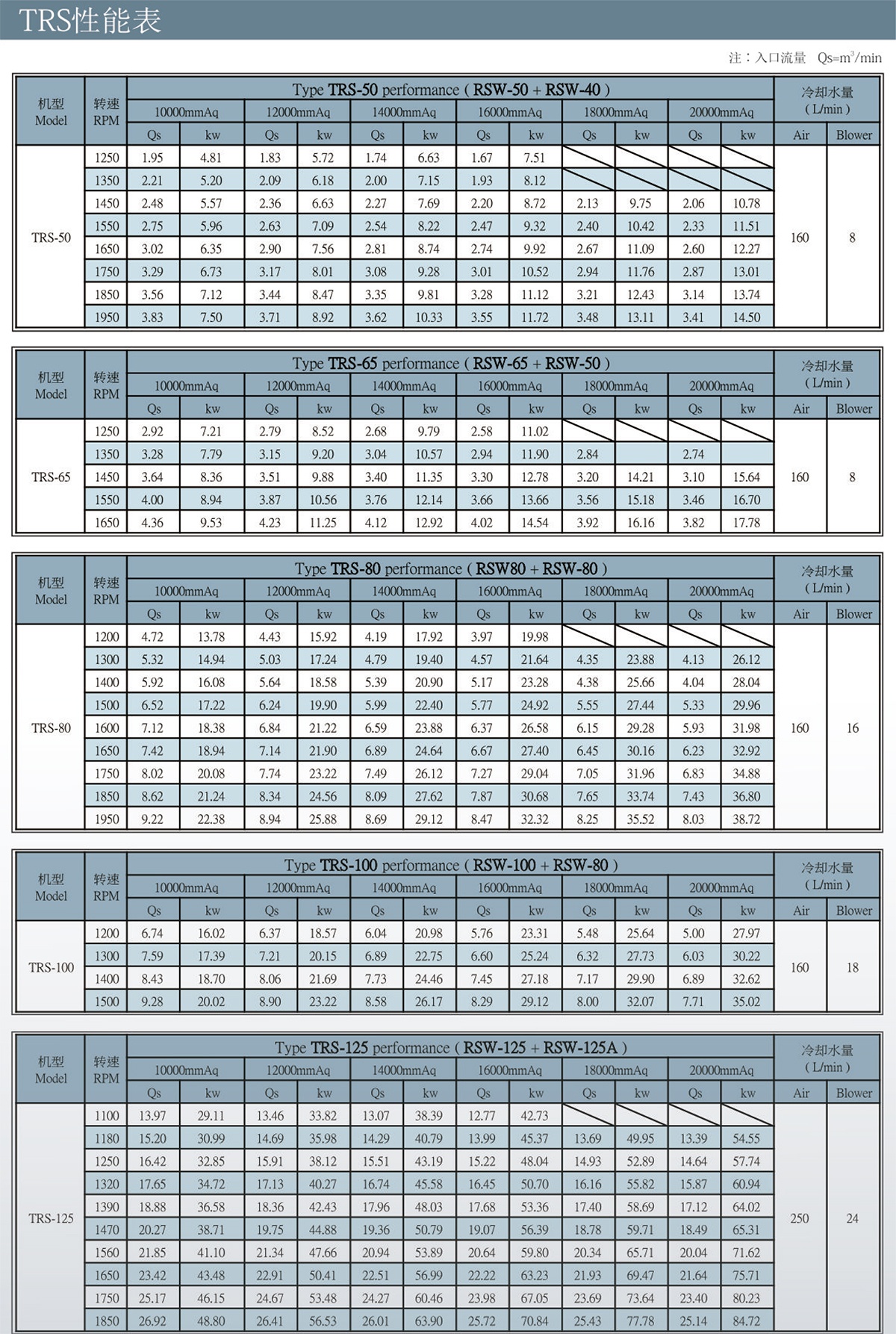

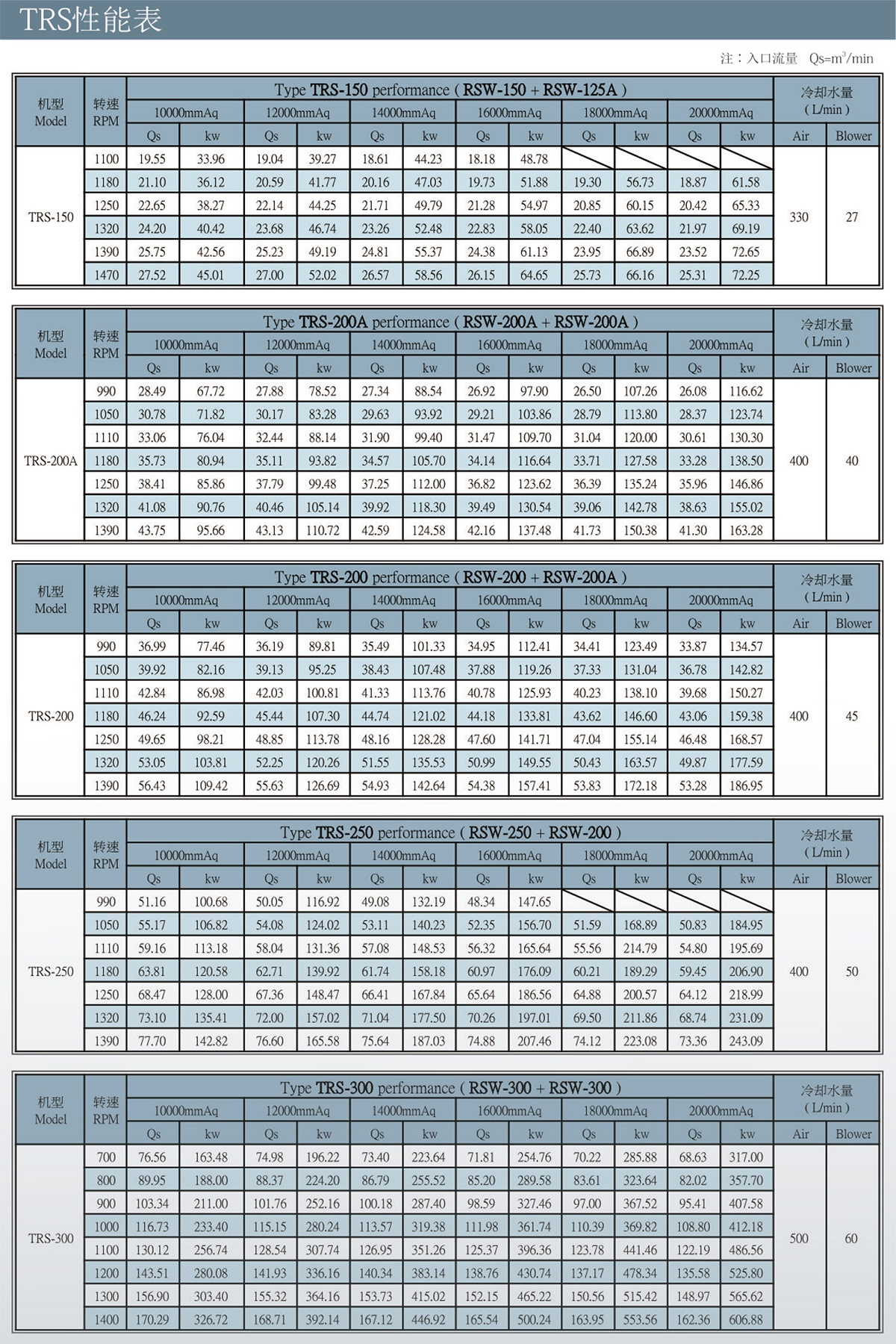

Air volume: RSW 0.36~162.23m3/min; TRS 1.14~166.49m3/min

Pressure: One-stage RSW type can reach 10000mmAq (1.0 kgf/cm2)

Two-stage TRS type can reach 20000mmAq (2.0 kgf/cm2)

The exhaust gas does not contain oil stains. The exhaust gas does not contain oil stains.

Computer dynamic balance correction, low vibration and low noise. Computer dynamic balance correction, low vibration and low noise.

The air volume is stable, and the pressure change has little effect on the air volume. The air volume is stable, and the pressure change has little effect on the air volume.

Special impeller design, high efficiency and energy saving. Special impeller design, high efficiency and energy saving.

The structure is simple and sturdy, and trouble-free. The structure is simple and sturdy, and trouble-free.

The use of first-class grinding gears has high accuracy, long life and low noise. The use of first-class grinding gears has high accuracy, long life and low noise.

Strict quality management, standardized products. Strict quality management, standardized products.

The impeller adopts the latest six-axis machining method of Longmen planer, which is completed in one machining, which makes it easy to replace and has higher precision. The impeller adopts the latest six-axis machining method of Longmen planer, which is completed in one machining, which makes it easy to replace and has higher precision.

The unique water cooling design can effectively reduce the temperature of the lubricating oil in the fuel tank and gearbox, and ensure the service life of the bearings and gears of the high-pressure operation of the fan. The unique water cooling design can effectively reduce the temperature of the lubricating oil in the fuel tank and gearbox, and ensure the service life of the bearings and gears of the high-pressure operation of the fan.

The two TRS wind turbines run in series, and through secondary pressurization, the fans achieve high pressure.The cooling system of the condenser can effectively cool down the gas discharged from the first stage of the fan, and the temperature at the inlet of the second stage is ≤40℃ to ensure the normal operation of the second stage of the fan. The two TRS wind turbines run in series, and through secondary pressurization, the fans achieve high pressure.The cooling system of the condenser can effectively cool down the gas discharged from the first stage of the fan, and the temperature at the inlet of the second stage is ≤40℃ to ensure the normal operation of the second stage of the fan.

|

EN

EN  The air volume and pressure range are large.

The air volume and pressure range are large.